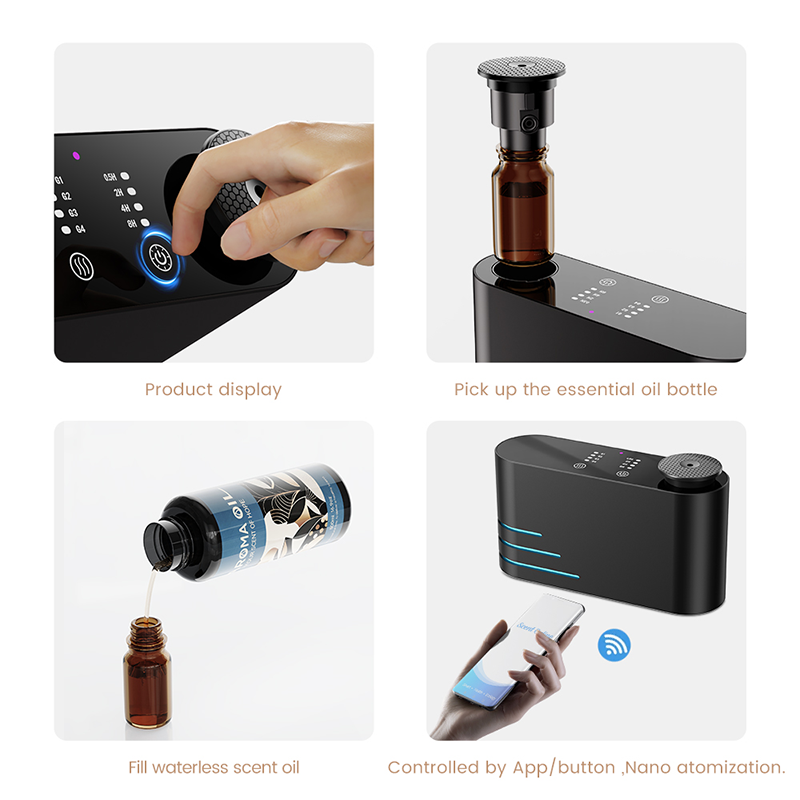

máy khuếch tán tinh dầu thơm

Máy khuếch tán tinh dầu thơm đại diện cho sự kết hợp tinh tế giữa công nghệ chăm sóc sức khỏe và thiết kế hiện đại, phục vụ như một giải pháp sáng tạo để tạo ra bầu không khí dễ chịu và trị liệu trong bất kỳ không gian nào. Thiết bị đa năng này sử dụng công nghệ siêu âm để chuyển đổi tinh dầu thành sương mát mịn màng phân tán đều khắp phòng. Hoạt động ở mức độ yên tĩnh như thì thầm, máy khuếch tán có dung tích bể chứa từ 100ml đến 500ml, tùy thuộc vào từng mẫu mã, cung cấp hoạt động liên tục từ 6 đến 12 giờ. Thiết bị tích hợp các tính năng tiên tiến như điều chỉnh mức sương, chức năng tự ngắt thông minh đảm bảo an toàn, và bộ hẹn giờ có thể lập trình cho phép vận hành tùy chỉnh. Nhiều mẫu mã đi kèm với đèn LED chiếu sáng tâm trạng với nhiều tùy chọn màu sắc, cho phép người dùng tạo ra bầu không khí hoàn hảo. Cơ chế siêu âm của máy khuếch tán phá vỡ tinh dầu thành các hạt vi mô mà không cần nhiệt, do đó giữ nguyên các đặc tính trị liệu của tinh dầu. Công nghệ này đảm bảo rằng những lợi ích tự nhiên của tinh dầu được phân phối hiệu quả đồng thời duy trì tính toàn vẹn của chúng. Thiết bị phục vụ nhiều mục đích, vừa là máy tạo độ ẩm, vừa là công cụ cải thiện tâm trạng và vừa là dụng cụ liệu pháp hương thơm, phù hợp để sử dụng trong phòng ngủ, văn phòng, phòng tập yoga và môi trường spa.